Sucker Rod Analysis

Structural Integrity Analysis and Field Development

Case Study of PT Pertamina Hulu Rokan

Structural Integrity Analysis and Field Development for Karamba Gas Transmission Using PHKT Pipeline

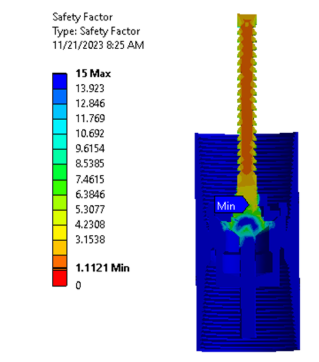

To analyze and verify the structural performance of the THORPED design using Finite Element Analysis (FEA). This research evaluates stress distribution, deformation, and safety factor to ensure reliability and safety under operational loads.

The THORPED design must withstand significant vertical loads, reaching up to 4000 psi, without compromising structural integrity. Ensuring that stress levels remain within material limits and preventing deformation beyond safe thresholds are critical challenges for operational safety and durability.

The FEA simulation results confirm that the THORPED design maintains stress levels below critical yield limits, with a maximum stress of 11,242 psi located at the centering nut. Maximum deformation recorded is 0.000962 mm, and the average safety factor is 14.098—well within the safe range, indicating robust performance and suitability for use under expected operational conditions.